A portion of the exhaust is channeled through an EGR control valve and proceeds to the EGR cooler. The EGR system is a high pressure loop, cooled EGR configuration. Schematic representation of a high-speed passenger car EGR/intake throttle system for Euro 3 application Figure 3 is a schematic representation of a passenger car type EGR system from the Audi 3.3 L V8 TDI Euro 3 engine introduced in 1999. The application of EGR is not limited to heavy-duty engines, but extends to engines powering light-duty vehicles as well. EGR system with one-stage cooling for Scania Euro IV engines In general, EGR can be cooled with engine coolant, ambient air or a low temperature liquid.

Engine jacket water is used as the cooling medium in the EGR cooler in this example as well. Pre-turbine (HPL) exhaust is routed via an EGR control valve and an EGR cooler to the engine inlet system. By 2008, the venturi flow meter was removed entirely.Īnother example of a cooled EGR system for heavy-duty engines is the Scania Euro IV system illustrated in Figure 2. Some versions also used pressure taps upstream and downstream of the EGR control valve to monitor the pressure differential across the valve for EGR rate feedback instead of a venturi-type flow meter. Early versions used a pneumatically actuated valve that was replaced with a hydraulically actuated valve and finally, the electrically actuated valve shown in Figure 1. Older versions of this engine (US EPA 2002/2004) had the EGR valve located on the inlet side of the EGR cooler.

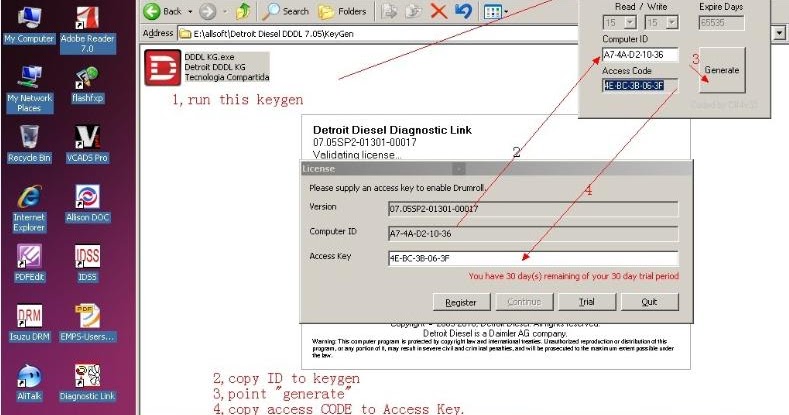

#DETROIT DIESEL DIAGNOSTIC LINK 6.4 SERIES#

Detroit Diesel Corporation US EPA 2007 Series 60 equipped with cooled HPL EGR systemĪ number of changes occurred in this EGR system from its introduction in 2002. The heater plate heats the EGR passing through the valve to ensure that ice does not form in the mixer housing. The EGR valve detail of Figure 1 also shows an EGR heater plate that is intended for use at low ambient temperatures. The EGR then passes to the intake manifold where it mixes with cooled charge air before being inducted into the engine. An EGR control valve located just before the mixer housing is responsible for controlling EGR rate. From the cooler, the EGR flows through an EGR pipe to the other side of the engine to a venturi-type flow meter that provides a feedback signal for monitoring the EGR rate. The EGR then flows through an EGR cooler provided with water from the engine jacket water.

The variable geometry turbocharger, among other tasks, ensures that the pressure difference between the exhaust and intake manifolds is positive to ensure adequate EGR flow is available when required. The EGR system is a high pressure loop (HPL) system where a portion of the exhaust is taken from upstream of the turbocharger. The EGR system for the DDC Series 60, Figure 1, is an example of the systems applied in many heavy-duty engines in North America for MY 2002 and later. Common examples include mixers using a venturi nozzle ( venturi mixer or venturi pump) and EGR pumps, also called EGR blowers, that are driven by an electric motor or by a mechanical connection to the engine. Most EGR systems include the following main hardware components:Ī number of other specialized components are possible in various types of systems. The configuration of an EGR system depends on the required EGR rate and other demands of the particular application. EGR systems are also used in many categories of Otto cycle engines, where the benefits may range from improved efficiency (reduced fuel consumption) to reduced methane slip in low speed dual fuel engines. The main components of EGR systems are EGR valves and EGR coolers.Įxhaust gas recirculation ( EGR) is a NOx emission control technique applicable to a wide range of diesel engines from light-, medium- and heavy-duty diesel engines right up to two-stroke low-speed marine engines. A number of considerations must be taken into account when designing EGR systems including: deposit accumulation, contaminants, engine lubricant, system packaging and more. Abstract: EGR systems have been commercialized as a NOx reduction method for a wide range of diesel engines from light-, medium- and heavy-duty diesel engines right up to two-stroke low-speed marine engines.

0 kommentar(er)

0 kommentar(er)